hardness test units 100 kg|standard hardness test methods : commercial Force is 1 kg +0.1 kg for Shore A, and 5 kg +0.5 kg for Shore D. . or by any other hardness test. [1] Shore Durometers of Common Materials Material Durometer Scale Bicycle gel seat: 15–30: 00 Chewing gum . and is in units . Resultado da Kiara Santos. Fale comigo agora. Chame agora no whatsapp. Ao chamar diz ter me visto no site Rc Love. Super Top. Acompanhante Mococa. Mococa .

{plog:ftitle_list}

Resultado da #Animation - Lucky Lūi's illustrations - pixiv . pixiv

Units of hardness. There are a variety of hardness test methods in common use (e.g. Brinell, Knoop, Vickers and Rockwell). There are tables that are available . Hardness comparison. A variety of hardness -testing methods are available, . Rockwell hardness is expressed in three scales: HRA: Uses a 60kg load and a diamond cone indenter, suitable for extremely hard materials like hard alloys. HRB: Uses a 100kg load and a 1.58mm diameter hardened steel .Hardness testing within the realm of materials testing. Today, hardness testing is one of the most widely used methods in mechanical materials testing, especially for metals. On the one hand, this test method can be used to find qualitative .

Force is 1 kg +0.1 kg for Shore A, and 5 kg +0.5 kg for Shore D. . or by any other hardness test. [1] Shore Durometers of Common Materials Material Durometer Scale Bicycle gel seat: 15–30: 00 Chewing gum . and is in units .

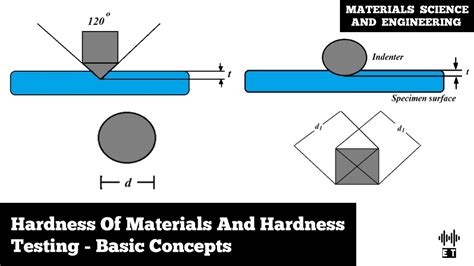

The Brinell hardness test consists in indenting the metal surface with a 10-mm-diameter steel ball at a load of 3,000 kg mass (∼29400 N). . Like the Brinell hardness, Meyer hardness has units of MPa. The Meyer hardness is less sensitive to the applied load than the Brinell hardness. . H = hardness, kg/mm 2 T = test temperature, K The choice is not only between the regular hardness test and superficial hardness test, with three different major loads for each, but also between the diamond indenter and the 1⁄16, 1⁄8, 1⁄4 and 1⁄2-inch diameter steel ball indenters. . 100 or 150 kg total test forces combined with diamond; 1⁄16, 1⁄8, 1⁄4 and 1⁄2-inch .The Vickers hardness test is ideal for testing of all metals and is therefore the method with the widest range of application. The hardness test method according to Vickers is described in standards ISO 6507 (Metallic materials – Vickers hardness test – Part 1: Test method) and ASTM E384 (Standard Test Method for Microindentation Hardness (1gf - 200 gf) of Materials .

Question: In a Brinell hardness test, a 1500-Kg load is pressed into a specimen using a 10-mm diameter hardened steel ball. The resulting indentation has a diameter = 3.2 mm(A) Determine the Brinell hardness number for the metal (B) If the specimen .

(120 degree cone 150 kg) Rockwell B HRB (1/16" ball 100 kg) Leeb HLD [1] 800-72-856 780: 1220: 71-850 760: 1210: 70-843 745: 1114: 68-837 725: 1060: 67-829 712: 1021: 66-824 682: 940: 65-812 668: 905: 64-806 . "Standard Hardness Conversion Tables for Metals Relationship Among Brinell Hardness, Vickers Hardness, Rockwell Hardness, Superficial .A modular manual/semi-automatic grinding and polishing system with a choice of polishers, specimen movers and dosing units for the ultimate in adaptability. TargetSystem. . The Vickers hardness test is often regarded as easier to use than other hardness tests: The process can be performed on a universal or micro hardness tester; the required .A minor load of 10 kg is first applied, which causes an initial penetration and holds the indenter in place.Then, the dial is set to zero and the major load is applied. . This dial like scale is really a depth gauge, graduated in special units. The Rockwell hardness test is the most used and versatile of the hardness tests. For soft materials . The commonly used units for hardness measurement are: Brinell Hardness Number (HB) Vickers hardness number (HV) . The standard load is 3000 kg, but it may be reduced to 500 kg for softer metals. For harder metals, a tungsten carbide ball may be used to prevent distortion of the ball. . Mohs hardness test uses 10 reference materials of .

3. In a Brinell hardness test, a 1500-kg load is pressed into a specimen using a 10-mm-diameter hardened steel ball. The resulting indentation has a diameter = 3.2 mm. (a) Determine the Brinell hardness number for the metal. (b) If the specimen is steel, estimate the tensile strength of .Question: 3 points (SI/USCS Units) In a Brinell hardness test, a 1500-kg load is pressed into a specimen using a 10-mm-diameter hardened steel ball. The resulting indentation has a diameter = 3.2 mm. (a) Determine the Brinell hardness number for the metal. (b) If the specimen is steel, estimate the tensile strength of the steel.In the Rockwell hardness test, a differential-depth method, . The scale division (basis h0 for the residual indentation depth h to be measured is 100 or 130 units (depending on the scale, the following applies: 1 unit E = 0.002 mm or 0.001 mm)). . The test pre-load for all methods is 3 kg. Method Indenters Main load (kgf)The Brinell hardness test is commonly used to determine the hardness of materials like metals and alloys. . Hardness B. Hardness C (ton f /in 2) (kg f /mm 2) (N/mm 2) 2.50: 601: 640-57.0---2.55: 578: 615-56.0---2.60: 555: 591: 120: 54.5---2.65: 534: 569: 119: 53.5--- . Unit Converter Temperature o C K o F. Length m km in ft yards miles naut .

Example: Let’s say we measure 100 PPM water hardness with a TDS meter. We can call that ‘100 PPM water hardness’, but you will also hear ‘100 TDS water hardness’). That also means that the TDS water hardness scale is the same .

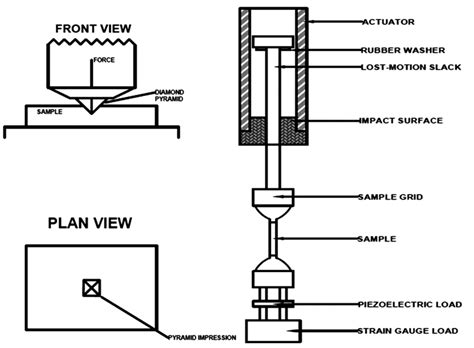

vickers hardness testing machine diagram

types of hardness testing methods

Before application of the Rockwell hardness test, you must prepare the surface of the material to be tested. The required surface condition for the Rockwell hardness test depends on the load used. The Rockwell hardness test is .

The loads applied vary from 1 to 120 kg; the standard loads are 5, 10, 20, 30, 50, 100, and 120 kg. For most hardness testing, 50 kg is maximum. The Vickers test can be used for all metals and is one of the widely used test among hardness .

Question: (SI/USCS Units) In a Brinell hardness test, a 1500-kg load is pressed into a specimen using a 10-mm-diameter hardened steel ball. The resulting indentation has a diameter = 3.2 mm. (a) Determine the Brinell hardness number for the metal. (b) If the specimen is steel, estimate the tensile strength of the steel.Show how you set up your .

This distance is converted to a hardness number. The preliminary test force is removed and the indenter is removed from the test specimen. Preliminary test loads (preloads) range from 3 kgf (used in the “Superficial” Rockwell scale) to 10 kgf (used in the “Regular” Rockwell scale). Total test forces range from 15kgf to 150 kgf .

Brinell Hardness Test. The Brinell hardness test entails measuring the diameter of indentation caused by a constant concentrated force applied by a steel or carbide spherical indenter on a test specimen. The steel ball indenter is first placed in contact with the material before a constant force is applied and maintained for a 10 to 15 second duration, known as the .Some of the commonly used hardness units include the Brinell Hardness Number (HB), Rockwell hardness numbers (HRA, HRB, HRC), Leeb hardness values (HLD, HLS, HLE), and Vickers hardness numbers (HV). . Similar to the Brinell hardness test, the Rockwell hardness test is utilized for measuring indentation hardness and involves the use of an .hardness test and is used in a wide variety of applications. Advantages of the Rockwell Test There are several reasons for the popularity of the Rockwell test. The test itself is very rapid. On a manually operated unit, a Rockwell test takes only five to ten seconds, depending upon the size and hardness of the specimen, as well as pre-load and .The Janka hardness test (English: / ˈ dʒ æ ŋ k ə /; [1] German:), created by Austrian-born American researcher Gabriel Janka (1864–1932), measures the resistance of a sample of wood to denting and wear. [citation needed] It measures the force required to embed an 11.28-millimeter-diameter (7 ⁄ 16 in) steel ball halfway into a sample of wood.(The diameter was chosen to .

Mohs hardness kit, containing one specimen of each mineral on the ten-point hardness scale. The Mohs scale (/ m oʊ z / MOHZ) of mineral hardness is a qualitative ordinal scale, from 1 to 10, characterizing scratch resistance of minerals through the ability of harder material to scratch softer material.. The scale was introduced in 1812 by the German geologist and mineralogist .It is applied to the specimen with a test force (to standard from 1 kg to 3000 kg) and held according to the holding time. To calculate the Brinell hardness, two perpendicular diameters of the test indentation are measured on the specimen surface. In addition, the test force N and the diameter of the spherical indenter are required.

The Brinell hardness (BH) test measures the hardness of rock (kg/mm 2) based on the displacement of a steel ball penetrating into a core sample exposed to a fluid over a certain period. For example, Carman and Lant (2010) conducted BH tests before and after the Marcellus shale samples were exposed to various treatment fluids. Their results .An alternative method is the Brinell hardness test, which uses a hardened steel (or tungsten carbide) ball indenter with a diameter D of, usually, 10 mm.This is applied under a load P of 500–3000 kg applied for 10–30 s.The diameter of the circular indentation d is measured in millimetres. The hardness number, (HB) is calculated using the following equation:

standard hardness test methods

load hardness tests vs depth

WEBAnimate Golden. Culona reventando vagina ( animacion hentai ) 4k 11min - 720p. Hentai. 6.2k 88% 29min - 1080p. anime. 238.5k 100% 26min - 720p. Sub hentai lirico. 1.1M .

hardness test units 100 kg|standard hardness test methods